Just a few weeks now until the BLOODHOUND team deploys the Car to Newquay for the first time. We’re planning to be down there before the end of September, to get the workshop set up in one of the old hardened aircraft shelters, ready to start testing at the beginning of October. That gives us just under 4 weeks to make sure everything works, and train the team on running our unique prototype jet car, before our first big runs on 26 October (Want to come and watch? Book here).

Engineering Ambassador to Kazakhstan

Engineering Ambassador to Kazakhstan

Global interest in BLOODHOUND is as strong as ever. While the engineering team is busy assembling the Car at our base in Avonmouth, the full-size BLOODHOUND Show Car is on display in Astana, the capital city of Kazakhstan, at their Expo 2017. BLOODHOUND is supporting the UK’s ‘GREAT Britain’ Campaign and promoting the excellence of British science and technology. We’re proud that BLOODHOUND continues to be seen as an ambassador project for the UK and excited that we’ll soon be able to show everyone the Car running for the first time.

As the Car comes together, I can’t help but focus on the cockpit as my newly-equipped ‘office’ takes shape. After weeks and weeks of bench testing with the cockpit innards assembled outside the Car, everything has now been transplanted back into the cockpit shell. It’s great to see it all coming to life and starting to control bits of the most advanced Land Speed Record Car ever.

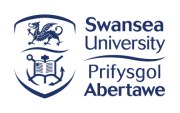

The suspension, wheel brakes and uprights (the large metal components that carry the wheel bearings and brakes) are now installed. The cooling water system (for cooling the electronics and the jet engine gearbox) has been filled and tested, and the (minor) leaks have been fixed. The rear lower chassis is now looking more complete, with the air ducts being installed to feed cooling air around the jet engine and the systems at the back end of the Car.

A story in 3D-printed carbon

A story in 3D-printed carbon

Even something as simple as a piece of ducting tells a fascinating story about the cutting-edge technology being used in BLOODHOUND. The complex air duct fittings have been made by ‘selective layer sintering’ (in other words 3D-printing) in carbon. This produces a tough and high-temperature-resistant component in almost any shape. Just what we need and, as this is very much next-generation technology, it’s also a great part of the story of our ‘Engineering Adventure’.

All in all, BLOODHOUND is starting to look more like a car every day. OK, perhaps not most people’s idea of a car, but I’ve got a picture of a 1000 mph Land Speed Record car in my head, and it’s starting to look like that.

The Car we test at Newquay next month will be a ‘minimum specification runway car’. In other words it will not have the rocket system, airbrakes or brake parachutes fitted, as we don’t need any of those for our ‘slow speed’ runs. The first few tests will also be done without the tail fin, which will be completed a few weeks later and fitted before we run the Car at the end of October.

Big engine, small intake

Big engine, small intake

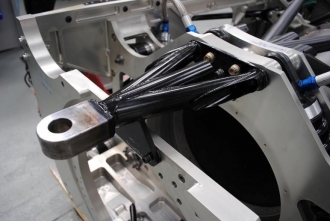

The test programme at Newquay will be split into 2 phases. The first phase is static tests of the jet engine and the Car’s systems. BLOODHOUND’s jet engine air intake has been carefully sized to deliver maximum power output between 800 and 900 mph. Unfortunately, this means that the intake is too small to feed our EJ200 jet engine all the air it needs when the Car is stationary. The result is that we can’t test the engine at full power until it’s moving.

The first question we have to answer at Newquay is exactly how much jet power can we get when the Car is stationary? Despite all the computer modelling (and there’s been a lot, thanks to Swansea and Rolls-Royce), we will only find out the exact answer by testing the jet with BLOODHOUND’s unique high-speed intake.

Attach airfield here

Attach airfield here

BLOODHOUND SSC will be rolled out to the old RAF tie-down facility (basically a huge steel ring set into the surface of a large concrete parking area) on the south side of Newquay airport. We’ll use a large steel tether to secure the Car to the airfield, to stop the Car running away when we start to test the jet engine (yes, it will be that powerful and no, the brakes won’t hold it).

The engine test schedule is about 6 pages long, as we need to test every control and indication at a range of different power settings. I may be in the cockpit for some time ... but the way things are going with the initial systems testing right now, I’m expecting the jet tests to go smoothly and quickly.

Once we’ve tested our jet engine/air intake combination (or, to use a more technical term, once we’ve ‘characterized’ the intake performance), we will know how quickly the Car is able to accelerate on the runway. That’s still a long way from knowing exactly how fast the Car can go at Newquay though.

How much grip?

How much grip?

The second phase of our testing will be ‘dynamic’ testing, to establish the rest of the details. First we’ll do a couple of 50 mph runs to bed in the carbon-carbon disc brakes that we’re using for the runway tests. After that we’ll do a 50 mph run to establish the grip level of the tyres. Aircraft tyres have a grip level of about 0.5 or 0.6 (that means for each 1000 kg of load on the tyre, we can generate 600 kg of braking force), which is around half of the grip you get from the tyres on your road car.

BLOODHOUND is using Dunlop aircraft tyres, originally designed for the old Lightning jet fighter. We’ve lowered the tyre pressure to give us the same size of tyre contact patch as the Lightning, so we’re expecting the same grip level of around 0.6 – to be confirmed in testing. We still can’t calculate the maximum safe runway speed yet. The next 2 runs, at 75 mph and 100 mph, will allow us to measure the aerodynamic drag and rolling resistance of the Car. The runway Car’s aircraft tyres and suspension are wider than the desert wheels, so we’ve left some of the bodywork panels off the runway car. This means more drag. For the 100 mph run, we’ll accelerate as quickly as the intake will allow (we’ll know by that point), then throttle back and let the car coast for up to half a mile before putting on the brakes. That will allow us to measure the total drag (rolling resistance plus aerodynamics) on the runway Car.

Ready for testing

Ready for testing

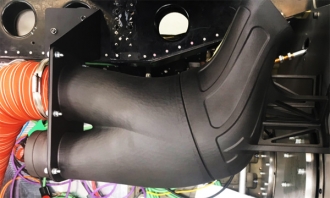

Still not quite able to predict the maximum runway speed though, as we need to confirm how much energy the carbon disc brakes can absorb. AP Racing has already tested the wheel brakes (you can see the brakes glowing red hot in this video of the test), but that did not include the airflow that will help to cool the brakes on the runway, or the aerodynamic drag that will help to slow the Car.

Once we’ve completed this final brake test (also at 100 mph), then we can calculate the maximum runway speed, which I’m still confident will be around 200 mph. We’ll know in a few weeks’ time.

So far, so good, but there’s a bit more work to do before BLOODHOUND’s first run in front of the public and the press at the end of October. The ops team at Newquay have promised us that October is a good month for weather in Cornwall, but this is the UK, so we have to be prepared for anything. We will aim to repeat some of the dynamic test runs on a wet runway (to check the grip limit), with a tail wind (to check the increase in stopping distance), and with a cross wind (to confirm the directional stability). Al the modelling shows that we can run the Car in a wide range of conditions, but we need to make sure.

If you haven’t booked already, there’s still time to book your tickets to see this astonishing piece of technology getting loud and angry for the first time. Thanks to Oracle and Cisco, we’ll be filming and live-streaming everything on the day, but that’s not quite the same as being there to see it for yourself. Newquay airport has agreed to us positioning the viewing area right alongside the runway, so it’s going to be quite a show.