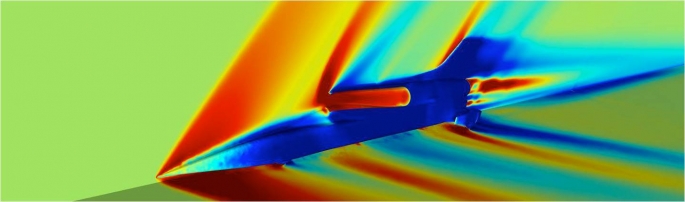

The aerodynamic refinement of the world’s first 1000 mph Car continues. The computational fluid dynamics work at Swansea University is giving us more data on the (now fixed) shape of BLOODHOUND SSC. Firstly, the good news. The ‘Configuration 12’ shape is producing exactly the right amount of lift – almost none. Any significant lift is obviously unacceptable, as the Car would fly. Significant downforce, like a racing car, is not much better – at 1000 mph it will be so high that the suspension will be hugely overloaded. So it’s a big relief that Config 12 produces no major changes of load on either the front or rear wheels, at any speed from ‘very slow’ (<200 mph) to ‘very fast’ (1000 mph+).

This is a terrific achievement by aerodynamicist Ron Ayers, working with Dr Ben Evans and the Swansea University team. In my opinion, it’s perhaps one of the most impressive technical achievements of the whole Project – and it means that the Car will stay on the ground at all speeds. After 5 years of work, we’re confirming that we have a fundamentally safe design. Speaking as the driver, this is great news!

Now to the not-quite-so-good news. While the lift is impressively low, the drag for Config 12 is slightly higher than our target. To get to 1000 mph, we need the ‘drag coefficient’, which is a measure of the drag per unit area of the Car, to be a maximum of 1.3. The Config 12 shape, as it stands, has a drag coefficient of 1.4 at maximum speed. So does this excess drag mean that we can’t reach 1000 mph? No – but we will have to refine the design to reduce it a little.

Current options are to make the top half of the Fin slightly thinner, and improve the wheel fairings. Little tweaks here and there can make a huge difference to the final result (ask any F1 team) so that’s the process we’re starting now. For another (light-hearted) view on drag, have a look at our latest Cisco BHTV episode.

The other thing to remember is that this is still a computer model, and this prediction may be a few percent more (or less) than the true figure. We won’t know the exact numbers until we get to the desert in South Africa next year and take the Car supersonic. If the drag is a little too high at that point, then we have time to make further refinements before the ‘very high speed’ (1000 mph) runs in 2014.

The HTP test rig allows the team to get the settings of the rocket motor just right in a laboratory setting

The HTP test rig allows the team to get the settings of the rocket motor just right in a laboratory setting

The drag target of 1.3 also assumes a rocket thrust of 122kN (27,000 lb). We’re now in the process of verifying this figure, with the first high-test peroxide (HTP) firing of the monopropellant rocket motor due in the next few days. This is Part 1 of getting the rocket thrust – proving that our Cosworth F1 engine can pump enough HTP through the silver oxide catalyst pack. Pumping nearly 40 litres per second at 76 Bar (over 1000 psi) is a huge task – which is why we need a Cosworth F1 engine as a pump motor, of course. Part 2 of the testing, the hybrid rocket firing to produce the full 122kN of thrust, will come later this year, and we aim to do it live on the internet – we’ll let you know when!

Work continues on the wheel brakes package, for both the UK runway tests and the desert runs. Current figures indicate that the runway brakes (carbon/carbon) will be able to absorb the energy of the Car from 160 mph – but that does not allow for aerodynamic drag. Add the extra drag from the airflow, and the brakes will probably be good for at least 200 mph, which is great news, as it will let us test full power on the runway before we go to the desert. Once out in South Africa, we will replace the carbon brake discs with steel discs, which are strong enough to survive the huge loads of spinning at over 10,000 rpm, but will probably be limited to a safe maximum ‘brakes on’ speed of about 100 mph. That should be fine – nearly all the braking is done by the airbrakes and parachutes on the desert.

The Cockpit Mould

The Cockpit Mould

The chassis build of BLOODHOUND SSC continues to go well. Hampson are pressing on with assembly of the lower chassis, while UMECO is starting to produce moulds that look like the front end of the Car.

Hyde is still refining the Fin structure, which will include a ‘bullet’ fairing along the top. This will house the video cameras that are going to relay live video pictures from the Car every time we run. We’ve also hit over 12,000 names on the Fin now – with more room still available if you want your name to travel at 1000 mph.

It’s a busy time of year for public engagements, with our Show Car out on the road at a number of BLOODHOUND events. The public’s interest at the Goodwood Festival of Speed was a busy as I’ve ever seen it, and we were also approached by some potential new sponsors at Goodwood (which is always nice!) – they were clearly impressed by the huge public interest in the Project. During the weekend, I joined BLOODHOUND rocket expert Daniel Jubb to present at the Goodwood schools event, and I also got a chance to drive the new Noble M600 – a 650 hp road car is a great way to do the Goodwood hill climb!

BLOODHOUND Radical looking fast at Goodwood

BLOODHOUND Radical looking fast at Goodwood

I’m doing some more driving in the BLOODHOUND Radical, as part of my training for 1000 mph. The Radical made a static appearance at the Fesitval of Speed, but has since been on the Goodwood race circuit this month – our thanks to the circuit team for letting me show some (quite nervous looking) journalists why track training is useful training for me.

The Air Training Corps – our future

The Air Training Corps – our future

We were also at the Royal International Air Tattoo at Fairford this month, watching the world’s largest military air show. BLOODHOUND was sharing (OK, mostly dominating) the education zone, which was enthusiastically staffed by the Air Training Corps. As well as promoting their great range of activities, they had around 600 cadets helping out with the organisation of the event (and able to enjoy a free air show into the bargain). If this group represents the future of the Royal Air Force, then it looks to be in good hands!

With the Car coming together month by month, I’m starting to think about the track in South Africa more often. There’s good news from the Northern Cape team this month, as they have now finished clearing the main track (all 10 million square metres of it), so I’m off to South Africa next week to see how they got on. I’m also going to meet up with the South African Motor Sports Association, who will be officiating for all our record attempts. The last time a World Land Speed Record was attempted in South Africa was by Malcolm Campbell in 1929, so this is not something they do very often. It’s something that they are determined to do well though – and with the Northern Cape team now finishing off the world’s best race track, it’s getting closer all the time.