As Project BLOODHOUND starts its preparations to run the Car in South Africa next year, the many complex pieces of our ‘Engineering Adventure’ are gradually coming together. This month, at the Farnborough International Airshow, we did our first ‘test load’ of the full-size Show Car into the 747 freighter aircraft that will take the Car, and all of its support equipment, to South Africa next year.

We’re very lucky to have the support of the new British cargo airline, CargoLogicAir, and their brand new 747-8F. This is the biggest 747 ever, and can carry an amazing 138 tonnes of cargo in a loading bay 60 metres long (think the length of a tennis court, then double it, then add another 12 metres…. It’s huge).

As discussed in last month’s diary, getting BLOODHOUND SSC and all its support equipment out to South Africa is a massive challenge. We will be surface-shipping about 15 container loads (around 100 tonnes) in advance, while we start to do our ‘slow speed’ (200+ mph) UK runway testing at Newquay Aerohub. Then we will fly the Car, its road trailer, and the rest of the support equipment out to South Africa.

Off to South Africa next year

Off to South Africa next year

That’s 100 tonnes to move 9000 kilometres by air, so that we can crack on with getting the Car up to around 800 mph (and a new Outright World Land Speed Record, of course) next year. CargoLogicAir’s 747 freighter is just what we need to make all of this happen. Having tried it at Farnborough, the good news is that BLOODHOUND SSC fits nicely!

Now that we have sponsorship secured and a target date for record runs of next October, the engineering plan is starting to show the detail that will get us to South Africa. The first order of business is for us to split the ‘dry build’ Car down to its component sub-assemblies. Every part will then be assessed for any remaining work (including final machining, painting, etc.), before being put into our stores at the BLOODHOUND Technical Centre down in Bristol.

The ‘dry build’ process is very useful for checking that everything fits together as planned (it’s amazing how things never quite look the same when they jump off the screen and become a solid part). It also allows us to check the things that are almost impossible to measure on a computer screen, like the space available to fit, service and (if necessary) replace a component. For example, the Car’s jet fuel tank fits well, but we can’t remove the access hatch on top once it’s installed. Inside the carbon fibre tank there is a flexible fuel bladder and, if this starts to leak for any reason, it will be a nightmare to fix. It’s an easy job to modify the tank lid now, so that’s what we’ll do, just in case we need to access the bladder out on the desert.

When everything is off the Car, finished and painted, we’ll start the reassembly process, getting the Car ready to run for the first time. If you want to see this process in action, then join our 1K Supporters’ Club and come down for one of our open days.

Simple idea, complicated to do properly

Simple idea, complicated to do properly

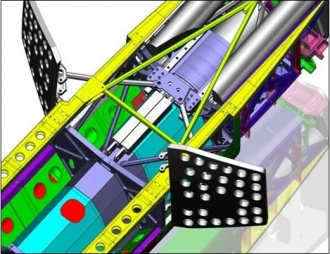

As well as the strip down of all the existing components, we still have a few bits left to manufacture. Major items are the big (and highly stressed) composite components, including the airbrakes and winglets. As these are safety-critical items, so they will be given plenty of attention to make sure we get them right.

The airbrake function sounds fairly obvious – put a couple of large flat plates out into the airflow to slow the Car down. They just need to be enormously strong to cope with 5 tonnes of aerodynamic load.

To make sure we can control the airflow, including the turbulence at supersonic speeds, the airbrakes are a fairly complicated shape, with a slightly curved surface and lots of holes to manage the frequency of the supersonic ‘buffet’, or turbulent flow, behind them. If you want to see how they are intended to work, have a look at our simple airbrake animation.

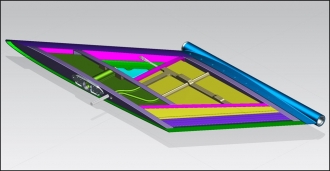

The winglets also sound like simple devices to make, with a fairly flat shape and straight edges. However, if we need to trim out any residual aerodynamic loads, they may have to take several tonnes of force at some point. Add a big safety margin and these carbon fibre ‘mini-wings’ need to be immensely strong.

Filming the action

Filming the action

Now add to the complexity by building in some surface pressure tappings (sensors), so that we can measure the air pressure distribution over the winglets. This is a very good way to measure precisely where the shockwaves are forming, and moving, as we go supersonic. A shockwave is literally a ‘shock’ change in the air pressure (it’s this sudden change in pressure that your ear detects as a loud bang – the so-called ‘sonic boom’), so the pressure changes on each winglet shows us where the shockwaves are sitting.

We’re not quite done with the winglet design yet, though. There are a number of areas where BLOODHOUND’s mission statement has a direct impact on the engineering, and this is one of them. We are going to ‘Create a unique, high-technology project, focused around a 1000 mph World Land Speed Record, share this Engineering Adventure with a global audience and inspire the next generation by bringing science, technology, engineering and mathematics to life in the most exciting way possible’. A big part of sharing our ‘Engineering Adventure’ with a global audience will involve video, including live streaming every time we run. This means cameras, and lots of them. BLOODHOUND SSC will be carrying 12 different on-board video cameras, including cameras on the tips of the winglets. This is where the ‘Adventure’ adds to the engineering task, as the cameras have to be built in to the winglet structure.

With all these cameras on board, we aim to make BLOODHOUND SSC the world’s fastest ever outside broadcast studio. We’ve already tested the desert comms system (which made for an amazing piece of video footage), but we still need to beam the signals off the Car. A South African company called Poynting has made us some very special aerials to broadcast the signal.

The aerials are hidden inside

The aerials are hidden inside

These will be mounted on either side of the Fin, broadcasting the video and data sideways to the 70 metre tall BLOODHOUND mast that MTN has installed at Klipkolk, some 14 km away. The aerodynamic fairings for these aerials will need to be ‘transparent’ to the high-frequency transmission signal, so they are made from a quartz fibre composite. Although not a strong as carbon fibre, for instance, the quartz fibre will allow the video and data signals to pass through it. The leading edge of the ‘strake’ (the bit at the front of the Fin, where it joins onto the top of the Car) will also need to be transparent to radio, as this is where the Car’s VHF radio aerial will sit.

Another major work package for next year’s runs is the testing and installation of the Car’s rocket system. With the 12 miles available on Hakskeen Pan, the EJ200 jet engine will get us up to around 700 mph before we need to slow down again, so getting to supersonic (760+ mph) speeds next year will require a bit more thrust. To keep it simple for our first year of testing, we’ll be using a ‘monopropellant’ rocket system. This is essentially leaving the hybrid fuel grain (i.e. the rocket fuel) out of the motor, and just using the energy contained in our high test peroxide (HTP) oxidiser. HTP is amazing stuff, used mostly for the chemical industry, as it is a very powerful oxidiser. Chemically, it’s a water molecule (H2O) with an extra oxygen atom stuck on to make H2O2.

Forcing the HTP through a catalyst (we’re using 80 layers of silver oxide mesh) will break down the bonds to release some (very hot) oxygen and lots of H2O (in the form of steam – it comes out at about 600 degrees C). The hybrid rocket then uses this super-heated oxygen to burn the synthetic rubber fuel, generating the thrust needed for BLOODHOUND to reach 1000 mph. Even without the fuel grain fitted, the HTP alone will generate nearly 50% of the thrust, which should be more than enough to get us supersonic. We’re aiming for around 800 mph next year. Of course, it’s not quite as simple as just leaving the fuel grain out. Next year’s ‘mono’ rocket will need specialist parts, and lots of testing, to make sure that it works as advertised. After all, this really is rocket science.

That is something the thousand of students who took part in the BLOODHOUND Model Rocket Car Competition will understand.

Over 5000 teams took part and our congratulations go to the Littlehampton Academy team, who clinched the national title with an impressive 48.4 mph from their car ‘Slim Jim’ (even the name sounds aerodynamic). If you want to take part in the 2016/2017 competition, then you’ve got until October to register here. Each team will get a free rocket car kit, and the excitement of doing their own science experiment, complete with electronic data recording, powered by a solid rocket. I don’t know about you, but that sounds more fun than any science lesson I ever did.