As we complete each piece of the BLOODHOUND SSC, the October runs at Newquay feel a little closer. The surprising part of this process is that there are a lot of engineering judgements to be made as we build up the Car. There’s a big difference between our previous ‘dry builds’ and the level of detail required to run a jet Car, even at the low speed of 200 mph.

Last week the front suspension was fully assembled, with the ‘uprights’ (the bits that hold the wheel bearings and brake rotors) in place and the carbon disc brakes fitted. All we needed to do was bolt the wheels on and the front of the Car would be ready to run. However, we then found out that there had been a couple of component failures in a batch of connecting parts that we were using.

This was unlikely to affect us, but the engineering decision was to change them anyway, for safety – a good call in my (largely uneducated) opinion. That’s why this week’s pictures on the BLOODHOUND website show the front suspension in pieces again, waiting for some new bits. It’s all part of building a brand-new race car for its first runs.

It’s all a matter of judgement

It’s all a matter of judgement

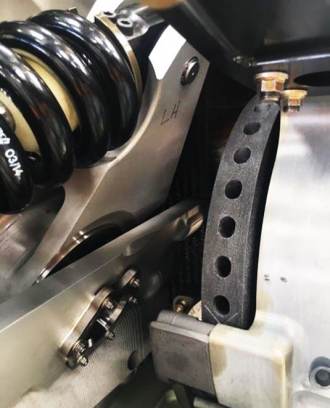

When we put the front suspension together, we found another very slight mismatch. With the suspension at full ‘droop’ (with the Car jacked up and the wheels hanging down unsupported), the springs should remain under slight compression (and we’re talking very small amounts here, perhaps 1 mm) to stop them being loose and rattling about. When we tried it, we found that the springs unload (and become loose) right at the bottom end of the travel.

For the rear suspension, we can fit ‘shims’ (very thin washers) under the springs to fill in the small gap and keep them under pressure. The fix for the front end is not so easy. Here’s where the engineering judgement comes in. The manufacturer can probably offer a quick and simple fix but, if not, then can we live with it? The simple answer is yes. It will just be one more thing to check when we jack the Car up or put it back on its wheels.

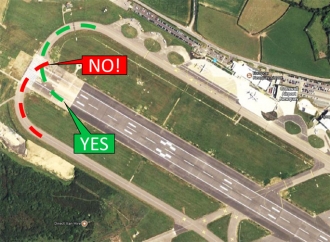

The Car may need jacking up more often than you would think. While Newquay airfield is an ideal test ground for BLOODHOUND, the airfield is designed for aircraft to move around, not for a Land Speed Record car with a huge turning circle.

It’s not designed for corners

It’s not designed for corners

BLOODHOUND SSC has a wheel base (the distance between the wheels) of 9 metres, with a lock of +/- 5 degrees at the front wheels, so (as you can no doubt tell at a glance) that gives it a turning radius of about 108 metres. That’s a turning circle of 216 metres, which comes under the technical heading of ‘gi-normous’. You can see how driving BLOOODHOUND round a normal airfield is going to be difficult. The Car will go round some of the wider corners at Newquay, but not the smaller ones.

I’ve got a map of the airfield in front of me, on which I’ve drawn a series of 220 metre arcs – green for corners the car will take, red for the ones it won’t. If the turn is really tight then the simplest solution is to lift the Car up, spin it round in its own length and drop it down again, so jacking the car could be needed several times in a day, depending on where we need to take it on the airfield.

Talking of Newquay, I’ve just got back from a meeting with the airport staff. They are as helpful as ever and just as excited as we are that BLOODHOUND will be in Cornwall soon for its very first runs. We’ve identified a fantastic location on the airfield for everyone to watch the Car run, right alongside the runway and next to the point where it will be at maximum speed. It’s going to be quite a show.

Jet power – the simple bit

Jet power – the simple bit

We’re putting a lot of focus at the moment on making the Car go. At the simple end of the chain (i.e. me), we’ve now set up the throttle pedal ‘detent’. This mimics the throttle arrangement in the Typhoon’s cockpit.

In the Typhoon, a detent or ‘gate’ is required between the dry power range (which varies the engine RPM) and the reheat range (where the throttle changes the fuel supply to the reheat flame at the back).

For the Car, we’ve fitted a simple spring-loaded wheel that bumps over a fixed stop, to give me a positive indication of the dry and reheat throttle ranges of pedal movement. While I’m really looking forward to getting the Car running in reheat down at Newquay, I don’t want to do it by accident!

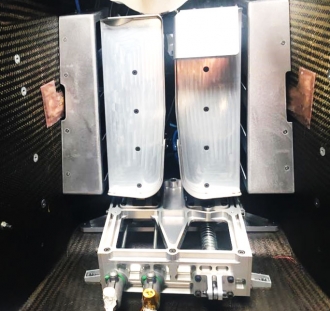

The rest of the engine control system is a little more complicated. The cockpit controls and displays are all being powered up ‘on the bench’, in other words out of the Car, where it’s easier to work on them – our latest Cisco BHTV gives a quick overview. The big difference from previous tests is that this time we’ve got the real jet engine attached at the other end, so that the cockpit and the Car’s computers are exchanging control signals with the EJ200 that will power BLOODHOUND at Newquay.

Jet power – the difficult bit

Jet power – the difficult bit

The testing is just about complete, after which the cockpit will be transplanted back in to the Car, ready for in-Car testing and our first jet engine start. Bring it on.

The big announcement for this month is our new technical partnership with Oracle. BLOODHOUND is all about telling the story of our ‘Engineering Adventure’. As we get ready to run the Car, we need a way to get the live video and data from our test track (Newquay this year, South Africa next year) to a global audience. In other words, we need a Cloud Services Partner – step forward Oracle. We’re really excited by this partnership, as it’s another key piece of telling our story to the widest possible audience.

I’ve just met the Oracle team and they are bubbling with ideas on how to turn BLOODHOUND into a captivating story. I don’t know about anyone else, but I can’t wait to see what they are going to do with BLOODHOUND Apps, Virtual Reality, and so on. If you want to see the Car run at Newquay, then please book your tickets here. If you can’t make it, then Oracle will aim to bring the Car to you.

In preparation for Newquay, the ‘Drive Tribe’ website is running a series of 100 Days of BLOODHOUND. I’ve just had a look at their page on 96 Days to Newquay Testing, where they ask what is (or isn’t) faster than BLOODHOUND. At the bottom end of the scale, I’m fairly confident that we can beat the Dacia Sandero’s 0-60 time of 14 seconds. The question gets more difficult with Concorde and some military jets. Supersonic jets can exceed 1000 mph at very high altitude, where the air is very thin. At ground level, though, where the air is much thicker, BLOODHOUND’s jet-and-rocket combination will beat the lot. 1000 mph is faster than any aircraft record at ground level, ever, so we win again.

Another long journey

Another long journey

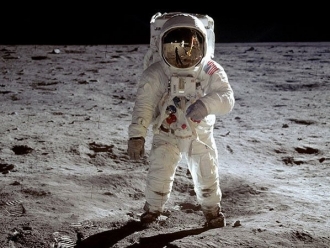

The one we can’t compete with on Drive Tribe is the Apollo spacecraft. I’m OK with that, as we’re not planning to go into space. We are trying to generate the same kind of excitement though, as we explained to Neil Armstrong when he came to visit BLOODHOUND a few years ago. We rather cockily told him that BLOODHOUND is aiming to be the ‘Apollo programme for the 21st Century’. He smiled and told us that was exactly what we should be doing. Thank you for your support, Neil – it’s been a long journey, but finally we’re getting there.