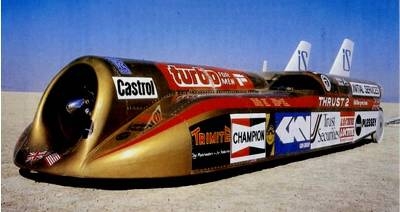

It was exactly 30 years ago that Thrust 2 broke the World Land Speed Record – 633 mph – and brought the record back to Britain. Until then, it seemed that the US had taken the record away from us for good, with all their new-fangled jet and rocket technology. Fortunately for Britain, a certain Richard Noble decided that we should get it back. When he set the record in 1983, he reminded us (and the rest of the world) that Britain was still a world-beater.

Another World-Beater

Another World-BeaterNow, 30 years later, we’re building something that would go past Thrust 2 like it’s standing still. BLOODHOUND SSC, the world’s first 1000 mph Car. We have the best motorsports industry in the world (if you need proof, just have a look at where all the Formula 1 teams are based) and one of the best aerospace industries (see the RAF’s world-class new Typhoon aircraft for further details). BLOODHOUND is going to be product of both industries, with a bit of space technology thrown in. It’s another world champion in the making.

The Car is being assembled at our Technical Centre in Bristol, and every time I see it more parts have been added. It’s also attracting attention from all over the globe: we’ve got over 200 countries following it on the BLOODHOUND SSC website.

Car Manufacture on the Move

Car Manufacture on the MoveOne of the impressive things about the build is the precision involved. For example, we are aiming to assemble the Fin to an accuracy of better than 1/12th of a degree.

The whole Car is being assembled with this kind of precision with the aid of a ‘surface table’ – a super-flat 7 metre long slab of cast iron which weighs 10 tonnes. The accuracy of the build is regularly checked using a Hexagon laser, which will measure the position of any part of the Car, in 3 dimensions, to one millionth of a metre. This has given us a bit of a problem, though, as the surface table (all 10 tonnes of it) keeps moving.

After a lot of checking, it would appear that the surface table, and the whole of our Technical Centre, is actually floating. The ends of the table move up and down by a couple of millimetres or so with the tide. We’re only a few hundred metres from the River Avon and the tide in the river makes the floor (and the surface table, and therefore our chassis) go up and down very slightly. If we’re fitting new components, the first thing we have to do is re-level the chassis, so that the new bits go on perfectly straight. No-one said that building a 1000 mph Car was going to be easy – but we didn’t expect to be afloat while we were doing it!

The Fin goes Here

The Fin goes HereThe last of the rear upper chassis ribs have now been delivered. These are the big heavy ribs that will have to support the Fin, while it’s keeping the Car straight.

The Fin has been stressed to take a 25kN (2.5 tonne) side load. I’m staggered by how much that is (we could lay the Car on its side and park 2 normal road cars on the Fin) and how little it is (at 1000 mph, the Fin will develop 25kN of side load at a yaw angle of only 0.9 degrees). Sounds like my driving might have to be as accurate as the chassis build – although the 2.5 tonnes of correcting force should help.

Your name goes Here

Your name goes HereDon’t forget that while the Fin is doing its best to keep us pointy-end forwards, you can be right there (or at least your name can). If you want your name to travel at 1000 mph, then sign up here to our Fin Programme.

There’s more good news from the aerodynamics team this month. We’ve been worrying about something called the ‘yaw static margin’ for a while now. The yaw static margin is the distance between the centre of gravity and the aerodynamic centre of the Car. In other words, this is what keeps the Car pointy-end forwards at high speeds. Ideally, we want the Car to look like a dart, with the weight up front and big feathers at the back.

We were worried that the static margin (a measure of how ‘dart-like’ the Car is) was smaller than we wanted. It turns out that we’d made 2 small errors in the calculation. One was in the aerodynamic model of the Fin, which hadn’t captured the latest changes to extend the trailing edge, so that made the centre of yaw move back a bit. The other change was finding an error in the (hugely complex) centre of gravity calculation, which moved it forward almost 300 mm. That’s a big gain, and suddenly the Car is looking a lot more stable. This will make it easier to keep the Car pointy-end forwards and, since that’s my job as the driver, I’m delighted.

Home Aerodynamics

Home AerodynamicsWhile we’re running the Car on the desert, one of the key things we’ll be checking is the wheel loads. These wheel loads are the result of the Car’s weight plus all the aerodynamic loads on the vehicle, so we’re going to be checking all the aerodynamic forces (and pressures) very carefully.

I’ve just seen a computer programme written by David Naumann, a PhD student at Swansea University. David’s programme will compare the real-world pressures, from 120 pressure sensors on the Car, with the predicted pressures from the Swansea computer model. This will allow us to check the Car’s performance very rapidly. We’re planning to publish the programme before we start running, so that you can check the Car’s performance for yourself at home, every time we run. It will also let the 5500 schools in our Education Programme follow the science as we test it. If your school hasn’t signed up to our free programme yet, then join the BLOODHOUND Education Programme here. It’s going to be quite an Adventure!

Open wide and say ’29 Tonnes’

Open wide and say ’29 Tonnes’URT is now finishing off our carbon fibre intake duct, which is essentially just a tube to feed air to the Car’s EJ200 jet engine. The intake was made in 2 halves and then bolted together to form the 2.2 metre long tube. It’s another part of the Car that will see some big forces. At 1000 mph, the intake will be pressurised to 1.6 Bar (24 pounds per sq inch), which will try to force the 2 halves apart with a force of 290 kN. That’s 29 tonnes. Put another way, each bolt that holds the 2 halves together will take a load of 13.2 kN, or 1.3 tonnes. So after parking 2 average-sized cars on the side of the Fin, we could pick each of them up in turn with just one bolt from the intake. That would explain why the bolts cost about £20 each!

If that wasn’t enough to worry about, the intake has also been designed to withstand an engine ‘backfire’ without collapsing. If the airflow into a jet engine breaks down, the jet can burp back the air it has been ingesting, known in the jet engine world as a ‘surge’. This could briefly push the intake pressure up almost 3 Bar (44 psi), increasing the load on the intake to over 50 tonnes. That’s the weight of 4 double-decker buses.

The EJ200 – we can see why the RAF likes it

The EJ200 – we can see why the RAF likes itThe bad news is that this load would pretty much wreck the intake. The good news is that we’re using the Typhoon’s EJ200 engine, one of the world’s best jet engines. In normal operation it just doesn’t ever surge. I can floor the throttle pedal (which controls the jet engine) at a standstill, and the engine will give me as much power as possible, without any risk that it will surge. The intake doesn’t have much to worry about – and neither do I.