After last month’s hugely successful public launch, we’re busy planning for next year’s trip to the desert. The target for 2016 is 800+ mph, after which we’ll upgrade the Car (principally with bigger rockets) for our 1000 mph record attempt in 2017. From my point of view, a key part of the planning now is around operating the Car. In other words, when I climb in to the world’s fastest race car next year, exactly what do I do next?

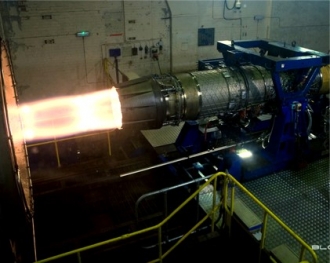

This might sound like an easy question to answer, along the lines of ’start the engines, drive really fast, then stop’. However, it rapidly gets more complicated than that. For example, I’ve got 3 engines to start up (the Rolls-Royce EJ200 jet engine, the Nammo hybrid rocket and of course Jaguar’s very fine five litre V8 ‘auxiliary power unit’ or APU, which powers the rocket pump. All of these engines have got specific requirements and restrictions.

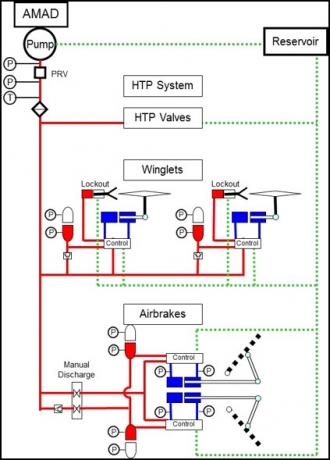

The Jaguar APU needs to be warmed up (to a minimum of 40+ deg C) before use, but the coolant system is only designed to support 20-30 seconds of rocket firing, so it will overheat if we leave the Jaguar engine ‘hot’ for too long. Starting the jet engine heats the inside of the Car, which won’t take long to start overheating the bodywork and the electronics, and in any case there isn’t much spare jet fuel on board. However, the jet provides hydraulic power to the Car, so we have to start the jet before we can power up the safety-critical items like airbrakes and winglets.  The hybrid rocket works by forcing concentrated hydrogen peroxide (known as HTP) through a silver oxide catalyst pack, which operates at 6-700 deg C, and needs pre-heating to around 400+ deg C before the Car starts moving.

The hybrid rocket works by forcing concentrated hydrogen peroxide (known as HTP) through a silver oxide catalyst pack, which operates at 6-700 deg C, and needs pre-heating to around 400+ deg C before the Car starts moving.

There are a number of other systems that need turning on and testing as the Car is getting ready to launch off down the desert. These also need a specific start up sequence, from the on-board video and data broadcast systems, which are transmitting even before I get to the Car, to the brake chute systems, which are armed just before the Car sets off.

Before writing the start-up and shut-down procedures for the Car, I need a clear idea of how the Car systems work. To make sure that my understanding is the same as the systems engineers, I’m working on some simple ‘Driver’s Notes’ to remind me of how everything should work and, in one or two places, to remind the engineers of how I’d like it to work!

BLOODHOUND hydraulics – the ‘Tube Map’

BLOODHOUND hydraulics – the ‘Tube Map’

For each system, there’s a simplified diagram to show how things connect up and where the cockpit readouts come from. This is what we mathematicians call a ‘topological’ map. Perhaps the world’s best known topological map is the London Underground. The ‘Tube Map’ is a very different shape to the underground tracks around London, but it shows you how it all connects and how to get to places. Aircraft systems diagrams take the same approach to teach pilots, so I’m copying this well-proven route. I don’t need to know the real shape of the systems as they thread their way through BLOODHOUND, just how they connect and how they operate.

This process is also useful to highlight areas where we might want to add extra sensors into the Car. For example, BLOODHOUND carries about 600 litres of jet fuel for a high-speed run. This is quite difficult to fit in to our narrow chassis (600 litres is about twice the volume of a domestic bath), so the fuel is split into three tanks. The main tank holds 400 litres, with two auxiliary tanks holding 100 litres each. The fuel is pumped from the auxiliary tanks to the main tank, then from the main tank to the jet engine.

The main jet fuel tank holds more than enough fuel for a full high-speed run, with the auxiliaries providing the extra fuel for engine start, warm up and cool down after the run. In the cockpit, I’m only interested in the main tank contents and the main tank pump, which feeds the jet engine. As long as the main tank remains full with the jet running, then the transfer pumps from the auxiliary tanks must be working.

Fuel pressure required

Fuel pressure required

The jet is able to ‘suck’ fuel from the main tank, using its own low-pressure mechanical pump, which will provide just enough fuel for the jet to run at idle power. It’s only when the Car sets off, and I push my right foot down on the accelerator pedal, that we’ll find out if the main tank pump is delivering enough fuel pressure. To make sure it’s working properly before setting off, we’re going to add a fuel pressure sensor into the main fuel line.

The operating sequence for the Car is still being developed, but here’s the first draft. Please don’t write in just yet to point out any errors, this is work-in-progress and our engineers haven’t even seen it yet.

Before the Car is rolled out of the hangar and onto the track, I’ll switch both batteries on to check that they are fully charged. The Car has two separate electrical 24 volt DC (direct current) systems, each with its own battery. 24 volts is the standard aircraft DC voltage, twice that of a normal car (partly for weight-saving reasons: double the voltage and you halve the current, making the wiring thinner and lighter). With power on, I can also check the readings on all 3 cockpit screens, and the ‘emergency’ screen setting – if one of the screens fails, I can push a button to move the central display onto the left hand screen.

Screen test

Screen test

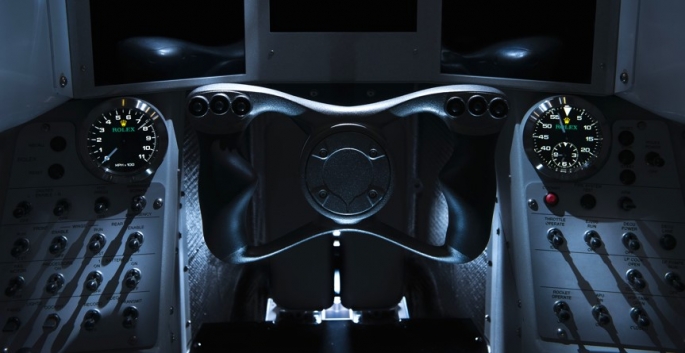

Before the Car is declared ready to go, the video system is fired up to check that all 12 on-board cameras are giving good pictures. It’s amazingly easy for one of us to dislodge a camera when we’re working on the Car, so now’s the time to fix it. Before roll-out, I’ll also check the cockpit breathing air system, the radio and the fire extinguishers (a total of 7 along the length of the Car). If you haven’t had a look inside the cockpit yet, have a look at the cockpit introduction video and the cockpit 360 view.

Once the Car has been towed to the end of the track, we’ll switch the power on again, turn the computers on (the Car has five, which control different bits of the Car, as well as checking each other) and turn on the video transmission system. This is a key bit of sharing our ‘Engineering Adventure’. We’re going to broadcast live video and data over the internet, every time we run, so that you can ride on board the world’s fastest Car as it runs, wherever you are in the world.

After checking all the support equipment is ready to go, I’ll climb in to the cockpit and strap myself in. First thing will be to start the on-board video recorders, so we’ve got our own record for both engineering review and later TV use. Power assisted steering will be turned on if I intend to use it (we don’t think I’ll need it, but it’s there just in case), I’ll check that the Rolex instruments have a good GPS lock and re-check all of the readings on the cockpit screens.

Next is the pre-run data entry, to tell the Car exactly how long the run is going to be, how fast I’m intending to go, etc. This will allow the Car to calculate and display the optimum points for me to fire the rocket, deploy the airbrakes or a brake chute, and monitor the track distance remaining. Back in 1997, I had to do a lot of this in my head, so I’m REALLY glad that modern technology can now do most of the work for me.

Strapped in

Strapped in

Once the data has been entered, we’re ready to start the Car. With the fire extinguishers armed, I can start the Jaguar APU and let it warm up. It will shut itself off when it’s warm enough, so I’ll just keep an eye on it. Next I’ll double-check the canopy hatch over my head is firmly locked down, then apply the wheel brakes with my left foot and check that both circuits produce the correct pressure, as it’s time to start the jet engine. The ground crew will connect the air starter that winds up the jet, then I’ll select low-pressure fuel pumps on, low pressure fuel cock open and engine on: the start sequence then completes automatically (I love modern technology). Stabilised idle is about 40% (jet engines measure output as a percentage of max RPM), the generator will now be online, providing AC (alternating current) power for the fuel pumps and, through something called a transformer-rectifier unit, converting that AC power into 28 volt DC to top up the batteries.

At this point, you may be wondering why I have to move so many switches to make all of this happen. Why can’t we just have a big ‘start’ button, which does all of this automatically? The simple answer is that we could. However, a quick look at some of the systems shows some good reasons for doing it the long way.

They all have a job to do

They all have a job to do

The Rolex instruments have their own internal power supply, to give me guaranteed accurate speed readings even if the main Car power fails. Leaving the Rolex instruments on would flatten their battery, so they are only switched on once the Car is powered up. If the video recorders were on all the time, we’d have a hard disk full of workshop footage and probably none of the actual runs. Power-assisted steering? Until we start driving, we don’t know exactly what the steering loads will be. Leaving the airbrakes, brake chutes, rocket system, etc. permanently ‘on’ has obvious safety implications. The list goes on. Having switches to control each bit is the best way to make sure that things happen (or don’t happen) when you want them to, in the right order, at the right time. It’s the way aviation works and it’s a system I know and trust: pilots have been doing it successfully like this for a long time.

With the jet engine running, the hydraulic system is at ‘idle’ pressure, which is still a healthy 90 Bar (1350 psi, which is about 40-45 times the pressure inside a car tyre). Selecting full pressure bumps this up to a massive 200 Bar (3000 psi). Now the safety procedures really kick in. Up to this point, the airbrakes have been manually isolated from the hydraulic system. As the start team turns the valves to connect them, the airbrakes immediately start to deploy – they are designed to ‘fail’ to the fully extended position, which is where I need them if there’s a problem with the hydraulics when the Car is running.

The airbrakes want to deploy

The airbrakes want to deploy

Once the airbrakes have deployed, I’ll select them back in and then test the normal system (the blue button on the left of the steering wheel), checking that each deployment and retraction meets the target time of four seconds. Once they’re fully tested and back in, I’ll power up the winglets and test them.

Nearly ready now. Arm the brake chutes, enable the rocket firing and jet throttle circuits, re-tighten my seat harness, and then ask the Run Controller for clearance to roll. While I’ve been starting up the Car, RAF Air Traffic Controller John MacLeod will have checked that everyone is ready, and the track is clear, so I’m expecting a quick response of ‘BLOODHOUND, you are clear to roll’.

Almost ready. The final bit is the rocket catalyst pack pre-heat. A quick stab of the pre-heat button on the steering wheel (middle button on the right) and the Jaguar engine pumps a small amount of HTP into the catalyst pack. This will immediately break down into steam and hot oxygen when it hits the silver oxide mesh: 2H2O2 → 2H2O + O2 + lots of heat. The cat pack should be above 400 deg C in a few seconds. NOW we’re ready to roll…. what happens next is another story.