It’s all in the Timing

This will be my last diary for a few months, as the day job (Fighter Pilot Royal Air Force) is taking me away for a bit. I will be based in Italy for 4 months, supporting air operations over Libya, but we’ll arrange some guest diary entries from the BLOODHOUND team to keep you up to date while I’m away.

Malcolm Campbell in South Africa, 1929 (photograph courtesy of Castrol)

Malcolm Campbell in South Africa, 1929 (photograph courtesy of Castrol)

Fantastic news last month – we confirmed Rolex as our Official Timing Partner. This substantial sponsorship deal will help us to get BLOODHOUND SSC built in time for testing and record runs in 2013, so it is very welcome. It is also a lovely link to the past – Malcolm Campbell wore a Rolex back in the 1920s and 1930s when he was setting all his Land Speed Records, and for his runs in South Africa in 1929, where he just missed setting a World Land Speed Record. Over 80 years later, we are going back to the Northern Cape with a Car capable of 1000 mph. I wonder what Campbell would have made of that?

The great record-breakers of the ‘20s created a huge amount of excitement with their amazing cars, which could exceed the astonishing speed of 200 mph. Now BLOODHOUND is creating the same effect with its global Education Programme – and we’ve just set our first World Record.

A new Guinness World Record

A new Guinness World Record

A group of pupils from Joseph Leckie Community Technical College in Walsall has spent the past year designing and building rocket-powered cars. At the end of May, they called in the man from Guinness World Records – they were ready for their record attempt. After several failed attempts due to technical problems, they finally cracked it – 88 mph across the school playground (picture above). A group of Year 9 students now have a fantastic experience of engineering and technology, and a new (scale rocket car) world record – well done them.

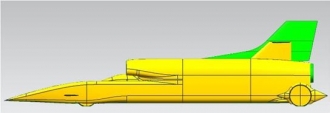

The new Fin – plenty of room for your name!

The new Fin – plenty of room for your name!

Good news from the engineering team. For the past several months, we have been working to develop a ‘positive yaw static margin’ for the Car – in simple terms, making the fin big enough to keep the car pointy-end forwards at high speed.

After some great work by the team, the fin is about 3 times bigger than it was originally, with a structural design to support the additional load. The profile of the nose has also changed, to reduce side loads on the nose.

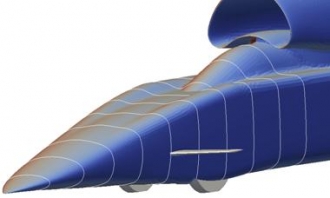

The rounder (and faster!) nose

The rounder (and faster!) nose

The net result is a Car that is now aerodynamically stable from below 300 mph all the way up to 1000 mph, which gets my vote! These changes have also reduced the aerodynamic drag on the Car, which makes it easier to get to 1000 mph – even better news.

Still staying with the subject of the Fin, over 8,000 people have put their name on it – a fantastic vote of support. We’re offering a free Gold Membership of our 1K supporters Club (which brings benefits such as a visit to the Bloodhound Technical Centre and trip to see a UK runway test), plus a special edition print, to the lucky person who signs up and becomes Fin Name No.10,000.

BLOODHOUND Engineer Brian Coombs with the first machined chassis part

BLOODHOUND Engineer Brian Coombs with the first machined chassis part

With the Car’s chassis now in manufacture, the first components are starting to roll off the production line. It was great to see the very first chassis part – a rear lower chassis corner, machined from aluminium – delivered last month. Only another couple of thousand parts to make and assemble and we’ll have a 1000 mph Car.....

Our recent brake disc tests showed that carbon fibre discs are close to bursting at 1000 mph, so we are looking for alternatives which can cope with very high rotation speeds. The current option is steel – it’s not a great material for a brake disc, but then it doesn’t have to be, as the brakes don’t do a huge amount of work on the desert. We’re now planning some brake tests to find out how well steel discs will cope – we’ll let you know.

Currently the largest hybrid rocket in the world – ready for UK testing

Currently the largest hybrid rocket in the world – ready for UK testing

The preparation for our UK rocket firing this summer is coming on well. This will be the first full-power rocket firing that we have done, with the liquid HTP oxidiser being pumped in by the Cosworth F1 engine for the first time. Our previous ‘part-throttle’ pressure fed firings were impressive enough, so this should be quite something.

I’m a little disappointed that I’m going to be deployed with the RAF when this happens, so all of you will get to see it on the news before I do. I won’t even get that chance to see it fire when we start testing the Car, as I will be in the cockpit.

Manchester Communication Academy (MCA) has become the home to the UK’s very first Bloodhound Education Centre. The Academy, BLOODHOUND sponsor Intel, approached us to offer space for an education centre. Launched three weeks ago, the BLOODHOUND Education Centre is the first of several across the UK and, along with the rest of the BLOODHOUND Project, aims to inspire the next generation of scientists and engineers.

After a very wet rainy season in South Africa, the desert has finally dried out, so the Northern Cape team will soon be able to re-start the track clearance work. This is going to be another of our world records before the Car runs – the Northern Cape is clearing 24 million square metres of surface (track and safety areas) for us, which is the equivalent of clearing a wide road from London to Moscow – by hand.

I’m off on operations now, helping the Royal Air Force to make the world a safer place – see you again in 4 months’ time. I’m already looking forward to catching with all the progress for the world’s first 1000 mph Car. It’s a real ‘Engineering Adventure’ and I can’t wait to get back to it.