The Pressure Mounts

The pressure is now starting to mount on the BLOODHOUND Design Office. With Hampson Industries poised to start building the Car’s chassis at the start of next year, we have to complete all of the chassis design and stressing (in other words, making sure that the Car won’t fall apart!) by Christmas. That’s a huge task – in order to complete the chassis, we need to fix the position of all the components of the Car – in addition to the jet, the rocket and the Formula 1 engine that will power the rocket pump, we need to finalise all of the systems, coolant tanks, the jet fuel and rocket oxidiser tanks, the rocket pump, the jet intake, jet starter motor, the suspension – the list goes on. We also have to fix the precise shape of the Car’s external surface, which means getting the aerodynamics exactly right.

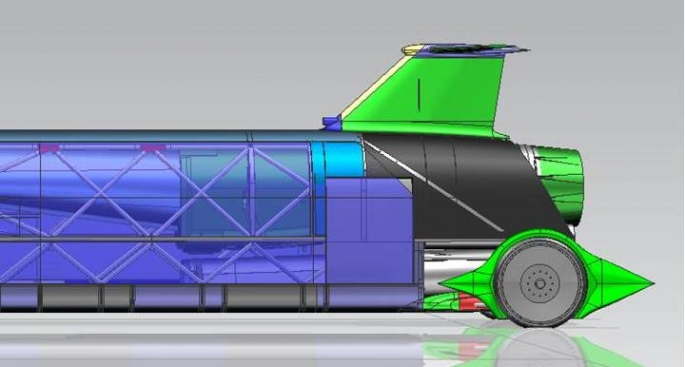

This external shape needs to be fixed by the end of October for the back half of the Car and the end of November for the front half, if we are to complete the chassis design by Christmas. We still have a few little problems to solve, though. For example, we’ve done a study of the heat build up during a ‘typical’ 1000 mph run – and the jet engine bay is going to get very hot inside. One way to keep it cool is to cut the bodywork back behind the fin.

I think the Car looks great with the proposed sloping back end (picture above) – but now we need to check that the aerodynamics are still OK before we finalise this change. And so it goes on – which is why the pressure is now on Chief Engineer Mark Chapman and the rest of the team. If anyone can do it, though, they can – and they will.

‘The Few’ – still full of beans, 70 years later

‘The Few’ – still full of beans, 70 years later

You may have seen the press coverage of the 70th anniversary of the Battle of Britain last month. It made September a busy month for me – a lot of people were looking for a modern take on the ‘Spirit of the Battle’. As a Fighter Pilot who is about to attempt a 1000 mph World Land Speed Record, I was invited to speak at a different event almost every night.

It was a privilege to be able to talk about ‘The Few’ who fought the Battle of Britain in 1940, the Spitfire and Hurricane pilots who prevented the German invasion and changed the course of world history.

It was also very special meeting some of the surviving pilots from the Battle. They are all about 90 years old now, but they are still full of life and great company – like their achievements, they are quite amazing.

We’ve sourced some critical components for the Car over the last month. In order to start our EJ200 jet engine, we ideally need a gearbox and starter motor from a Typhoon aircraft. Unfortunately, as you would expect, all of the available gearboxes and starters and being used on the Royal Air Force’s Typhoons.

We got our prototype jet engine from one of the Typhoon development aircraft so, after a bit of searching in scrap yards and museums, we’ve now found a prototype gearbox and starter as well. It’s more high-tech recycling, BLOODHOUND style. Now we can start the jet engine – which will make the Car work so much better.

Lightning tyres – just what BLOODHOUND needs

Lightning tyres – just what BLOODHOUND needs

We’ve also taken delivery of 12 tyres originally made for the Royal Air Force’s Lightning fighter, which went out of service in the 1980s. These tyres are a very unusual shape for a jet aircraft, very tall and thin – just the same shape as a Land Speed Record car’s wheels.

Both Thrust 2 and Thrust SSC used them for UK runway tests – and it’s a good solution, so BLOODHOUND is going to do exactly the same for our ‘slow speed’ (250 mph) tests. These ‘old’ tyres have been delivered to Dunlop for a full inspection and re-life, before we use them early in 2012 on a UK Runway. Want to come and watch BLOODHOUND SSC run in the UK? We are going to have a special test day just for our Supporter’s Club Gold Members – join the Club and come and watch something unique!

Bird vs jet fighter at high speed – no winners

Bird vs jet fighter at high speed – no winners

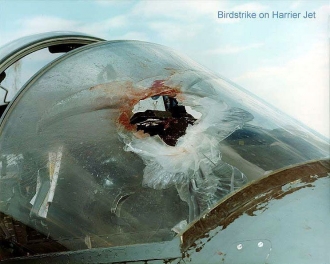

Another subject of discussion this month was the thickness of the Car’s windscreen. How thick does it need to be? It has to protect me against the aerodynamic loads (12 tonnes per square metre at 1000 mph) and, in the worst case, against a bird strike. As a rough figure, a 25 mm thick windscreen can stop a 1 kg bird at 1000 mph (or so I’ve been promised).

All well and good – but some of the birds in South Africa weigh a LOT more than 1 kg – and we can’t make the windscreen much thicker, or I won’t be able to see through it. We’ll just have to make sure there are no birds on the track before I set off.

Some good news from the Northern Cape this month. We will survey the whole track next year, once we’ve finished clearing it, but in the meantime we surveyed a 2 km strip in the middle of the track to check the flatness of the surface.

Hakskeen Pan – checking for lumps

Hakskeen Pan – checking for lumps

The biggest variation over 2 km was just 61 mm – astonishingly flat – and the Car’s suspension will easily cope with this surface. A frequency analysis of this data also shows that there are no bumps near the ‘natural frequency’ of the suspension, which might make the Car bounce up and down uncontrollably – this is also very good news from my point of view.

The Northern Cape Government held a ‘BLOODHOUND Event’ out on Hakskeen Pan last month, to tell the locals more about BLOODHOUND and what we are planning. Our Track Boss, Rudi Riek, was a guest at the event and the saw the reaction of the hundreds of local people who turned up: ‘the people of Mier (the nearby town), had never dreamt that their pan, always there and not really of much use to them in the past, would now become a beacon of hope, an asset that will put them in the eye of the world, and a way to put food on their tables for many years to come’.

I was touched by those words and by the effect that our Project is already creating. Better yet, the Northern Cape is planning to send some local school students to the UK to see the Car under construction next year – another part of the BLOODHOUND Education Programme in action.

I was touched by those words and by the effect that our Project is already creating. Better yet, the Northern Cape is planning to send some local school students to the UK to see the Car under construction next year – another part of the BLOODHOUND Education Programme in action.

It’s not just our team that’s excited about 2012. We’re going to make a real and positive difference to the Northern Cape and, I think, to kids all over the world. That’s the aim of the whole Project and, through the Education Programme, it’s already starting to happen. I can’t wait.