Welcome back to the Noble Monthly Report! The last one was in December 2011 and I daren’t call these quarterly reports or else you would only get them annually! Andy Green manages a monthly report on the BBC website which sends our web stats soaring, but here I have a real problem – Bloodhound is growing so fast that not only what I write is instantly out of date, but money making has to come first and the financial pressures are very considerable – (to use bankers' shorthand for one Hell of a ride!). We grew the company by 100% last year and we have to grow another 125% this year.

So let's bring you up to date. 2012 is the year in which we get Bloodhound onto its wheels and we get all the detail design completed. We also get the rocket programme through its safety and acceptance firings. All this against a British economy which is stagnating and which is about to be seriously affected by the Diamond Jubilee and then the Olympic Games when few will able to do any work. The Bloodhound design team is expanded now with another two designers to come after Easter and huge progress is being made. There is a massive buzz through the company as all this comes together and we can see how the 30 man years of research has really paid off and there is huge confidence in the design and the team. At our base in Bristol the lower floor has been cleared out for assembly and the fullscale plastic show car will never go back there again. Chris Dee is in control and the stores and the clean room have been completed. Work pushes on at Hampson. Amada, Jaivel the Advanced Manufacturing Research Centre and Umeco: the parts list is growing as the designer team sign off the drawings. October, November and December are the months for assembly - the parts and assemblies have to be completed before and I am worried that the combination of the Jubilee and the Olympics will set everything back as the country closes down.

As usual Bloodhound is a massive counter culture fight - the usual parade of would be sponsors either say no or make no decision which also means no. But suddenly things are changing – we are detecting substantial change. Companies and people are looking for the Next Big Thing after the Olympics and of course there isn’t anything – the money has been blown on the Grand Jamboree. But there is Bloodhound – and Bloodhound is now in 5,000 UK schools. And there is growing interest in the US and in South Africa. And so there should be, Bloodhound is now in every country in the World with the exception of 15. We are having particular problems with Vatican City, so if anyone is on friendly terms with The Pope, please give him a nudge!

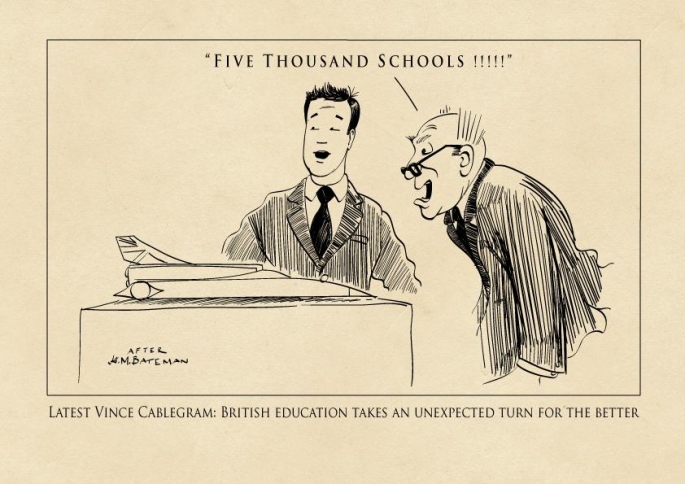

FIVE THOUSAND SCHOOLS !!! That was the response from deputy Prime Minster Nick Clegg and Business Secretary Vince Cable when Conor La Grue nailed them at the BIS Manufacturing Summit and Conference. After a huge effort to wake up our leaders as to the scale of what was happening – Conor got the message right in at the top. The result of this is that I have been summoned to 10 Downing Street to explain Bloodhound. It would be good if all this were recognised with some kind of support.

FIVE THOUSAND SCHOOLS !!! That was the response from deputy Prime Minster Nick Clegg and Business Secretary Vince Cable when Conor La Grue nailed them at the BIS Manufacturing Summit and Conference. After a huge effort to wake up our leaders as to the scale of what was happening – Conor got the message right in at the top. The result of this is that I have been summoned to 10 Downing Street to explain Bloodhound. It would be good if all this were recognised with some kind of support.

The education programme is developing very fast – in fact so fast that the small Bloodhound Education Team are looking forward to the Easter Break when there’s a chance to draw breath, put tired feet up and review the first crazy months of the year. Last year. Graham Lockwood's team drove our transporter 34,000 miles between schools shows and exhibitions – this time we expect 50,000 miles plus. And now there is a new dimension started by Leader of Northamptonshire Council Jim Harker. Jim came up with the idea of immersing all the schools in Northamptonshire in Bloodhound since Northamptonshire is about manufacturing and the importance is to develop local skills and interest on a grand scale. Bloodhound is contracted to present to 100 schools and 12,000 school children and this starts in April. Another four Counties are making noises about doing the same. But Bloodhound isn’t about building the education team into a massive industry. We need to keep small motivated and exceptional – and so after the Education Team has presented to schools, we need the Bloodhound Ambassadors to take on the local support while the education team moves on to the next schools. The Ambassadors are joining large numbers - and also sponsors are now commissioning Bloodhound to train their people as Ambassadors; IMechE, GE, Rolls-Royce, ARCO, CISCO, Metaswitch – this is really good. The Ambassadors have a crucial role to play in all this and we need a quality cadre of capable people to take their local schools forward while we get on with running the Bloodhound SSC in South Africa. Now that we have so many volunteers, we have to restructure to give them maximum help and support. The Bloodhound Education Team is becoming a huge success with an ever increasing demand. The contribution to the overall project in terms of generation of goodwill and sponsor support is very considerable.

At long last I was able to get a trip down to South Africa to see the Hakskeen Pan (HKP) for myself. There were a few days available and I met up with the Northern Cape Government in Kimberly and reported on progress in UK, then together with Peter McKuchane we set off for the long drive to HKP via the very beautiful town of Upington on the famous Orange river. HKP lies in the Kalahari Desert very close to the South African/Namibian border and the place is beautiful desert country and very remote. One of the fascinating sites on the road to HKP are the special road signs which allow motor manufacturers to test their high performance cars up to 250KPH on the straights in high temperature conditions. Prototype cars are flown from all over the World to conduct tests on this very special road.

Of course the HKP desert was still flooded after the rains, but somehow we got the cars to the point where the old road used to cross the desert on its causeway and I was able to walk to the mid point of the track. Frankly the surface is the best and most consistent I have ever seen. I called Andy who confirmed that the desert surface is consistent right across the 12 mile stretch from end to end.

Of course the HKP desert was still flooded after the rains, but somehow we got the cars to the point where the old road used to cross the desert on its causeway and I was able to walk to the mid point of the track. Frankly the surface is the best and most consistent I have ever seen. I called Andy who confirmed that the desert surface is consistent right across the 12 mile stretch from end to end.

The next day I was back in Upington for the team meeting. 28 people mostly from the Public Works Department turned up and I was able to give them an update of where we are with the project. Their achievement is considerable – the causeway road has been removed and over 6,000 tonnes of stone removed in appalling arid desert conditions in 40C of heat. The meeting was very ably run by Mr Nogwili otherwise known as HOD (Head of Department) and I felt a huge affection for these truly wonderful people who had decided to back Bloodhound right from the start of the programme, when 10 members of the Government had made the trip to Bristol so meet our team.

Mr Nogwili made the point for all of us ‘Failure is not an option’

The next tranche of finance is in place and the local people will be back on the desert in April when the surface dries. I am going to join them just as soon as I can get back.

Back in Johannesburg it now seems that with the help of our good friends at MTN we now have the technology to get the data off the car and onto the internet. The last pieces of the jigsaw are coming together.

Another HOD was raised last week, Henry O’Neal de Hane Segrave – aka Sir Henry Segrave. Ben Cussons at the RAC Club in Pall Mall London had decided that the RAC needed more motoring content and decided to hold a dinner to celebrate Segrave’s 200mph record in March 1927. Sir Henry on arrival back in England travelled straight for London and dinner at the RAC. Mine was a most welcome escape from another night of Bloodhound accounts and we had a superb RAC dinner to honour the memory of a most extraordinary man. Segrave fought in the trenches in 1915, joined the Royal Flying Corps the next year was shot down and somehow survived WW1. He then set about life in earnest winning 8 major international motor races taking the World Land Speed Record in 1926, 1927 and 1929 and then was killed in freak accident on Lake Windermere having regained the World Water Speed Record at 98mph in Miss England II. He also created the very first business aircraft – the Segrave Meteor. He raised the World Land Speed Record from 146mph to 231mph, an amazing 85mph or 58%.  How on earth a man could compress

How on earth a man could compress  such a huge level of achievement into just 33 years? What on earth could he have achieved if he had lived on? I am very proud of my 1930’s print of Golden Arrow breaking the record and signed by Segrave (HOD Segrave as he signed himself) and I keep it in a dark room so his ink doesn’t fade.

such a huge level of achievement into just 33 years? What on earth could he have achieved if he had lived on? I am very proud of my 1930’s print of Golden Arrow breaking the record and signed by Segrave (HOD Segrave as he signed himself) and I keep it in a dark room so his ink doesn’t fade.

Back in Bristol the Assembly Hall is brightened up with the most beautiful Rolex clock which ticks off the minutes and unrelenting, reminds us that December and roll out is not so far away!

The rocket programme is late. It's a very long time since Daniel Jubb fired the 18 inch rocket for the first time – the video is mighty impressive - but the HTP was being pressure fed with nitrogen to avoid the use of the pump (which was not ready) and only running at 300psi . Matching the pump to the Cosworth engine and creating all its supporting hardware software has been a massive job and hopes were raised at the end of last year that we could progress to firing, but we couldn’t. An audit showed that we still had a long way to go in engineering, critical parts were not ready and the all important documentation was weeks away despite huge commitment by Cosworth and Rainham Industrial Services. The previous six months had been a battle to find a suitable test site. Various sites were tried in sequence with massive paper trails and risk assessments but it's a long time since Britain fired a big rocket and there was every kind of concern raised. I came to the conclusion that the operational knowledge had to be relearned - the old knowledge and experience had retired along with the last generation of scientists and engineers. The Falcon rocket is the largest hybrid ever made in Europe and generates 186 dB of noise which I am told is 25x the noise level of a jumbo jet taking off – but it's only for 17 seconds! To cut a very long and tortuous story short, we now have a site, we have the paperwork and the whole act together and we start the preliminary testing later this month. It's not been easy and since we have yet to pump HTP we still are unsure whether we have correctly matched the pump to the very peaky race engine. Get it wrong and the engine won't make max revs, the pump won't deliver to target and the rocket thrust and specific impulse will be down, which is unacceptable.

And all this makes a crucial point about rockets. With Thrust2 and ThrustSSC, we fitted existing and well developed military engines with all their airframe installation and controls robbed from fighter aircraft. Progressing to a bespoke rocket development is a huge undertaking best done by a Government! It's not enough to get the rocket to fire and shoot impressive levels of flame and noise. It has to achieve its performance targets (thrust and specific impulse) and if it doesn’t then the whole car power to weight ratio is compromised and Bloodhound will not achieve its performance targets. A huge effort has been put in by the design team to get the car weight, drag and stability right – poor rocket performance will compromise all their efforts.

Will the rocket development run easily this year? It would be brilliant if it does – and after all this huge effort, there is every chance that the pump and its systems will work well. But there could well be another Gotcha around the corner that will make things difficult for us. We have just got to work up to the Hybrid firing and hope that our thinking and logic has this right. And when we fire the rocket later this year we are going to make all the rocket data available so you can start to get a feel for the huge scale of the programme and learn about rocket technology.

The project is facing considerable challenges this year – every pound made has to go into the engineering and manufacture. And this is why we are not going to be at the Farnborough Airshow, which we have always attended in the past. In 2010 we showed the plastic show car for the first time and we had a superb pavilion. The organisers generously paid for us to attend and the pavillion was provided free. This time the organisers made it plain that they wanted to promote Bloodhound to bring all the schools in but they would not pay a fee and there would be no detached Bloodhound pavilion. Farnborough is a mammoth aerospace show with the presentation standard set by the contractors feeding largely off Government contracts. It's a hells expensive operation for us – to do this properly we need engineering team members on site and the show runs for an exhausting 7 days. Farnborough raised hopes of sponsorships in the past but the aerospace industry is financed by Governments and the industry really only has governments and airlines to please. We would lose money, lose production and it would cost us a bomb - the only winners would be Farnborough International who could use our presence to bring more visitors and children through the gate. The stark choice was Farnborough and losses, or more engineering and production – so we chose engineering. So very reluctantly we declined – and so our big event this year is going to be the Goodwood Festival of Speed where we’ll put on a major show for everyone .

One of the problems facing us is that of presenting the project and its engineering – the scale is so large now that it takes hours to cover the ground and to make sure that the audience understands the detail of the Bloodhound Project . So we are producing a Bloodhound manual which will be available off the web very shortly. The book will be written by the end of this week and into production amazingly quickly. Look out for it on the website – every hard copy is going to be numbered.

The pressures are very considerable – can we bring in the next sponsors in time to maintain cashflow - can we get the rocket to work efficiently and get through our safety and acceptance firings this year? Can we really get all those parts made in time – and can Chris Dee and the team get the car onto its wheels by Christmas? Are we going to get the remainder of the desert cleared by November? And is Britain going to shut down over the summer?

Bloodhound has never ever been easy and this year is a seriously tough one – and we are all going to make it through together.

Richard Noble March 31st 2012