“Watching paint dry? It’s far more exciting when it’s a supersonic car!”

During the last few days of May progress on BLOODHOUND SSC took another leap forward. This time it was cosmetic, but that in itself speaks volumes about the stage we have now reached in the build.

The monocoque receiving its livery of blue and orange in a state-of-the-art spray booth at 3M’s training and development centre at Atherstone.

The monocoque receiving its livery of blue and orange in a state-of-the-art spray booth at 3M’s training and development centre at Atherstone.The monocoque has been evolving over a very long time, but now it was time to finally get it painted. Thanks to 3M we had access to a state-of-the-art spray booth at 3M’s training and development centre at Atherstone. And thanks to Akzo Nobel we are using the very latest technology in Aerospace coatings – all expertly applied by Simon Evans of Paint by Simon.

Seeing the monocoque with paint on it suddenly makes it feel more purposeful yet again. This will be followed in the next few weeks by all the big bits of car getting painted. For any aircraft or car build seeing what you’ve designed and constructed with colour on it is a great moment – it changes your view entirely and signals the start of a new stage in the build.

High performance, lightweight paint

The Akzo Nobel paint is no ordinary paint. It’s the very latest in super performing aerospace coatings, which is able to meet the challenge of big variations in temperature and pressure as well as being very, very tough. And it’s ultra-lightweight too.

It’s going to be interesting to see just how tough the paint actually is, but then that’s the rolling laboratory nature of the car! There is no more challenging application than BLOODHOUND to test our partners’ products.

Oh, and it makes the Car look good too!

Planning the final assembly

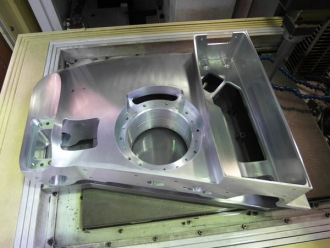

The rear uprights are some of the most complex machined parts made for BLOODHOUND, with a huge number of features held to very tight tolerances.

The rear uprights are some of the most complex machined parts made for BLOODHOUND, with a huge number of features held to very tight tolerances.As we start to plan the final assembly stage the last few key parts of the suspension are nearing completion. The most dramatic of these are the rear uprights. These are truly stunning but also are some of the most complex machined parts we have had made, with a huge number of features held to very tight tolerances. The first of these uprights will shortly be shipped to us at the BLOODHOUND Technical Centre and we can then start to work towards getting the Car onto its wheels for the first time.

That will mean we will soon be lifting the Car off the surface table and starting the final build on very special axle stands on the floor of the workshop. This is all carefully planned – for example, these stands are lined up with the door to make it easy to load the Car once completed.

Bringing up the rear

The rear delta helps to manage shock waves and keep the Car on the ground.

The rear delta helps to manage shock waves and keep the Car on the ground.The rear delta has also progressed quickly during May, with Terry from BLOODHOUND and Royal Air Force 71 Squadron again showing us just how skilled they are by quickly getting both delta assemblies to the stage that we could offer them up to the back of the car.

We always knew the car was narrow, but with only the rear uprights outboard of the delta you can see just how narrow the back of the car is going to be!

People often ask what keeps the car on the ground. Ultimately, it’s all about managing shock waves and no car part works harder to accomplish that than the rear delta. So it’s nice to see all these parts come together and be right first time.

Fitting out the Car

With so many primary parts nearing completion it’s the secondary parts and systems that will then take the time. Only once the big bits are finished can they be populated with all the gear that brings the Car to life.

However, the good news is that the fin and the delta are close to their final build stage and then the control systems team will have access to populate them with all manner of sensors and looms. It’s fantastic – if slightly unbelievable – that they will effectively be completed before the end of June.