BLOODHOUND eyes electrical future

BLOODHOUND Project Engineering Team to investigate electric motor to drive the rocket fuel pump

Maturing battery technology offers design and build flexibility for BLOODHOUND SSC

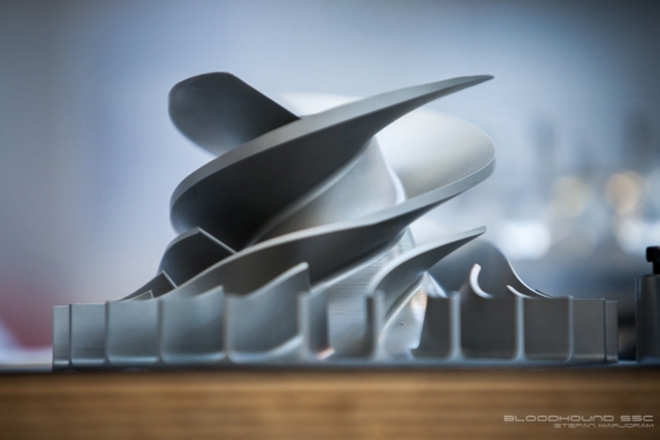

The BLOODHOUND Project’s Engineering Team is to investigate using an electric motor to drive the rocket oxidiser pump in BLOODHOUND SSC, the world’s most advanced straight-line racing car. An electric motor would be significantly smaller than the current auxiliary power unit (APU) – a 550bhp Jaguar Supercharged V8 engine – and provide greater flexibility in the location of components within the Car. It would also offer a great opportunity to showcase the potential of an electrical automotive powertrain.

BLOODHOUND Engineering Director Mark Chapman said: “BLOODHOUND has always sought to push the boundaries of technology. However, when the Team last looked at an all-electric solution for the APU, suitable motors did exist but the battery technology was not mature enough to provide a realistic packaging solution. Since those early discussions, two things have happened – the Team has further developed the pump, dramatically improving its efficiency, and battery technology has moved on immeasurably, to a point where a packaged solution can be developed.”

“BLOODHOUND SSC is already completing its first trial runs very successfully at Cornwall Airport Newquay and the vast majority of the design and build is now complete. But the BLOODHOUND Project never stops developing and we are always looking at emerging technologies. An investigation into an electric powertrain will allow the Project to maintain currency with the current direction of automotive technology and in addition allow us to showcase the potential that exists today.”

The switch to using an electric unit within the Car’s powertrain has been made possible by the increase in power and reliability of batteries over recent years, alongside a reduction in cost. This has had a huge impact on the automotive industry where the move to electric and hybrid vehicles is seen as a way to cut harmful emissions. The potential benefits for BLOODHOUND SSC are different, however. In this Car, one of the greatest challenges is accommodating all the components, including multiple braking systems and engines, and their fuel/power supplies.

A petrol engine APU is not only larger than the equivalent electrical unit would now be, but also requires the relationship between the engine, clutch, gearbox and pump to be fixed as a single entity, along with the need for a closely positioned air intake, fuel and oil system. Conversely, although the position of an electric motor still has to be fixed relative to the pump, the remainder of the system – including the motor controller, battery packs and so on – can be more flexibly positioned within the Car, and even separated if necessary. This gives far more packaging opportunities for the engineers within the Car. One thing both systems will require is cooling, using the water tanks on either side of the monocoque. However, as there is no need for a cooled air intake for the electric option, again, the system for the electric alternative could be simpler.

Incorporating an electric motor in the Car still presents challenges, but ones which the Team see as an exciting opportunity to explore the boundaries of what an electric motor can achieve. Not only will it have to perform in very extreme physical conditions, including high temperatures, intense vibrations and desert dust, but it will also have to deliver its power in around 20 seconds, which is in marked contrast to how it would be expected to perform in a road car. Similarly, the Team has less than 1 hour to turn the Car around between the two runs required to set a World Land Speed Record, which will require either very rapid battery recharging or a highly efficient way to swap out the battery units.

Mark Chapman adds: “We’re convinced that the technology is now at a stage that will allow us to use an electric solution and are keen to work with companies in this field to explore what’s available and how it can be integrated into BLOODHOUND SSC.”

– Ends –

For more information, interviews, imagery and videos

Contact: Jules Tipler jules.tipler@mettlepr.com/ +44 (0) 7811 166 796

Notes to editors

The BLOODHOUND Project is an international education initiative focussed around a 1,000mph (1,609km/h) World Land Speed Record. The primary aim is to inspire the next generation of scientist and engineers by showcasing STEM subjects (science, technology engineering and mathematics) in the most exciting way possible.

BLOODHOUND SSC is a combination of fast jet, F1 car and spaceship. The Project is followed in over 220 countries and territories.

At full speed, BLOODHOUND SSC will cover a mile (1.6km) in 3.6 seconds – that’s 4.5 football pitches laid end to end, per second, or 300m in the blink of an eye.

The World Land Speed Record of 763mph (1,228km/h) is held by Thrust SSC, a UK team led by BLOODHOUND’s Project Director Richard Noble and driven by Andy Green.

The Project engaged with over 130,000 students in the UK alone in 2016 and aims to deliver BLOODHOUND educational events to 3.5 million students around the world.

65% of students engaged by the BLOODHOUND Education Programme would now consider engineering or science as a vocation (sample size: 1,804).

Applications to study engineering at university have increased as a result of Project BLOODHOUND (sources: University of West of England; University of Swansea).