300 people clearing Hakskeen Pan

This is a difficult update to write because I can’t really describe in words the scale of what is happening in South Africa.

I’ve just got back from a technical survey of the desert work (and some media interviews, to explain how we are getting on) and I’m still amazed by what I’ve seen. I was with a couple of experienced journalists, who were fairly quiet over dinner after their visit to the Pan, as they tried to grasp the enormity of what they’d just seen.

The Northern Cape team (all 300 of them) are achieving something truly astonishing in the scale and quality of their work. So far, they have cleared the whole of the main track, 19 km long by 500 m wide, and they are now working their way back up the western side of the track, clearing a 300 m safety zone to give BLOODHOUND SSC some run-off area in the (unlikely) event that it’s needed.

The Northern Cape team (all 300 of them) are achieving something truly astonishing in the scale and quality of their work. So far, they have cleared the whole of the main track, 19 km long by 500 m wide, and they are now working their way back up the western side of the track, clearing a 300 m safety zone to give BLOODHOUND SSC some run-off area in the (unlikely) event that it’s needed.

Think about the scale of that for a moment. 19,000 by 500 m. That’s 9,500,000 square metres of desert surface, cleared by hand. Try and visualise it this way: next time you stand next to the road you live on, imagine sweeping one lane of it from end to end. If you live on a long road, this rapidly becomes a huge task. 9,500,000 sq m is the equivalent of sweeping that lane from London to Moscow – and now that they have reached Moscow, they have to turn round and sweep the other lane back to London, to complete the safety zones. It’s simply staggering.

To make that even more impressive, the team is not just walking along and picking up a few stones as they go. They are scraping the WHOLE surface, every square metre of it, to remove ALL the debris, however small. Have a look at this video, filmed during an afternoon working alongside the team.

You can see how the team is scraping the surface completely clean, and also notice how hard and consistent the surface is. It gives you an idea of just how much care they are taking, and also why I think we’ve found the perfect surface for a Land Speed Record attempt – Hakskeen Pan really is going to be the best race track in the world.

One other thing that the video doesn’t show. After an hour, I was starting to feel quite tired – this is physically hard work. Yet this team of 300+ are doing this for 8 hours a day, day in and day out. I hugely enjoyed meeting them and seeing their motivation and excitement about BLOODHOUND, and the energy they put into the work, but after an hour of working with them, it was also very humbling – this really is an amazing, world-class effort. It made me very proud of what they are achieving.

One other thing that the video doesn’t show. After an hour, I was starting to feel quite tired – this is physically hard work. Yet this team of 300+ are doing this for 8 hours a day, day in and day out. I hugely enjoyed meeting them and seeing their motivation and excitement about BLOODHOUND, and the energy they put into the work, but after an hour of working with them, it was also very humbling – this really is an amazing, world-class effort. It made me very proud of what they are achieving.

The remaining technical challenge for the Northern Cape is the final levelling of the causeway. This man-made soil road, built decades ago as an all-weather route across the Pan, is being removed back to its original state, with the soil being placed back in the ‘borrow holes’ on the Pan, where it originally came from. The challenge now is to make the original surface perfectly level again. We already know that the natural desert surface is remarkably flat, as our mini-survey showed a couple of years ago (‘Hakskeen Pan: How Flat is it?’). Now we need to reproduce this flat surface under the causeway.

For most levelling tasks, a change of level of 10-20 mm over 100 m wouldn’t matter much (it wouldn’t even be noticeable). For BLOODHOUND however, which will cover 100 m in less than a quarter of a second at peak speed, a 20 mm change of surface elevation qualifies as a huge bump! The Northern Cape has tasked ‘the best grader driver in the South Africa’, with a precision laser-guided grading vehicle, to complete the final cut, aiming for an accuracy of 10 mm across the whole of the area. It’s not just the Car that needs to work to very high precision – this is a really tough target for the track as well. Work is due to start this month, so we’ll let you know how they get on.

For most levelling tasks, a change of level of 10-20 mm over 100 m wouldn’t matter much (it wouldn’t even be noticeable). For BLOODHOUND however, which will cover 100 m in less than a quarter of a second at peak speed, a 20 mm change of surface elevation qualifies as a huge bump! The Northern Cape has tasked ‘the best grader driver in the South Africa’, with a precision laser-guided grading vehicle, to complete the final cut, aiming for an accuracy of 10 mm across the whole of the area. It’s not just the Car that needs to work to very high precision – this is a really tough target for the track as well. Work is due to start this month, so we’ll let you know how they get on.

BLOODHOUND ‘Track Boss’ Rudi with the Cone Penetrometer

BLOODHOUND ‘Track Boss’ Rudi with the Cone Penetrometer

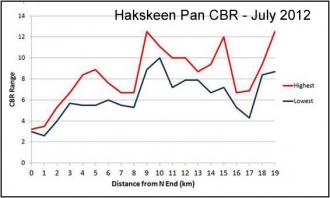

The other thing we tested during this visit was the surface hardness. This is measured using the Cone Penetrometer – and because the surface at Hakskeen is so hard, we used the California Bearing Ratio (CBR) scale to assess it.

The minimum hardness to run BLOODHOUND is a CBR of about 3 (which is equivalent to the Black Rock desert surface that we used for Thrust SSC in 1997). As you can see from the graph, Hakskeen is generally much harder than that, which is ideal for us.

The minimum hardness to run BLOODHOUND is a CBR of about 3 (which is equivalent to the Black Rock desert surface that we used for Thrust SSC in 1997). As you can see from the graph, Hakskeen is generally much harder than that, which is ideal for us.

You need 4 things to set a World Record: a world-beating Car: a world-beating Team, the Resources to pay for it – and a world-class Track. We’ll have BLOODHOUND SSC on its wheels at the end of this year, we’ve already got a world-class team working on it, we’re gradually getting enough support to complete the build – and I’ve just seen the best race track in the world being prepared. Thanks to the Northern Cape, Project BLOODHOUND is coming together.