We have received the following report from Phil Worsley at the Joseph Whitaker School in Mansfield ...

Hiya Bloodhound!

The group and I (and our Head) thought you would like to see our pictures and videos of what we have done with our stomp rocket cars and track.

We have done quite a bit more work on the cars and track and had so much fun ... we even had our Head – Rob Martlew jumping on the Stomp rocket launcher!! (see the list of YouTube videos at the bottom of this email).

We are pretty well finished with the design and development – I and my Young Engineers are doing the fun bit of testing, development and will be running the project with our primary schools. My head of department has caught the ‘stomp bug’ and will be developing the paper resources. Our Head has already offered funding to buy sufficient resources to run the project – which will be mid May to June 2012 when the primary schools curriculum is a little quieter.

Here are some pictures of the final bits and pieces. We decided to make a launcher and track to

- hold the cars in a uniform position prior to launching – this is also safer in terms of someone holding the launch tube and another bod ‘stomping’ close to them!

- and to direct the cars – this became a very apparent need as even the best designed cars by the group swerved all over the place. By adding a track that would guide the wheels of the cars, it allowed all the cars to travel much great distances and also meant that we could measure how well a car was constructed – in terms of distance travelled which would be determined by axle friction and aerodynamics.

We have made 8 sections of 2.4 metres each giving a total of 19 metres ... I honestly thought that no cars would get to the end, but we have video evidence that they can!

The track sections being manufactured. They are simply two 6mm MDF sheets. The upper one is cut to 80mm wide. This is the agreed inside width between the wheels of the cars

The track sections being manufactured. They are simply two 6mm MDF sheets. The upper one is cut to 80mm wide. This is the agreed inside width between the wheels of the cars

Here are four of the completed tracks. they can overlap each other and the leading sections are slightly tapered so that there are no edges for the cars to hit as they pass from one section to another.

Here are four of the completed tracks. they can overlap each other and the leading sections are slightly tapered so that there are no edges for the cars to hit as they pass from one section to another.

This is James and Elliot designing their own Polystyrene cars. This was a great success as you will see in the vidoes and will allow our primary students to experiment with shapes that are easy to develop.

This is James and Elliot designing their own Polystyrene cars. This was a great success as you will see in the vidoes and will allow our primary students to experiment with shapes that are easy to develop.

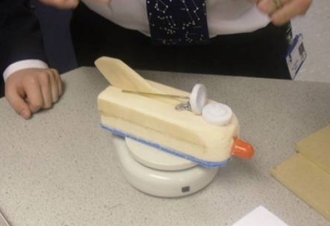

The same students are measuring one of the Stomp rockets (without its tail flights) to. Right is a picture of a rocket being sandwiched into a polystyrene shape. It is important to firmly fix the rockets in place or they can (and have) shot off leaving the car behind!!

The same students are measuring one of the Stomp rockets (without its tail flights) to. Right is a picture of a rocket being sandwiched into a polystyrene shape. It is important to firmly fix the rockets in place or they can (and have) shot off leaving the car behind!!

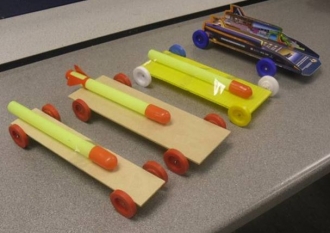

Below are pictures of the range of chassis and shapes that we have so far produced. We are going to supply each primary school with a kit that will include an MDF chassis, wheels, axles, axle bearers and blocks of foam. The chassis element will be very similar to the MDF one 2nd from the left on the top right photograph.

Top left and below – pictures of a number of completed ideas. Foam and paper mache. We have also decided that weight will be measured as one of the areas for assessment.

To make the competition a bit more interesting and fun, I aim to design and make a large format speed trap that measure the cars speed via a set of laser diodes that will (with a bit of magic) calculate each cars initial speed after 2 metres.

Below are links to all the videos on YouTube we have for this project so far. Permission has been given at all levels for their use.

http://youtu.be/Gu7lWGHWSV4 - Very first test of stomp rocket and car. This is a video of a test of the launcher with one of the completed cars

http://youtu.be/cTwMaI72pX8 - First ideas of track design and testing

http://youtu.be/8AYl3JY0hvk - A video of the launcher mechanism that allows for different heights of the rocket and is fixed to the first section of track to ensure that the car is correctly aligned with the track

http://youtu.be/YrmfjTrHJKw - To compare the balloon powered car built at the Bloodhound event our girls went to, to one powered by ‘stomp’ power – see next video!

http://youtu.be/P8gD8B1H6mw - The paper mache ‘Bloodhound car in comparison to the Balloon powered car... a brilliant view of the speed that the car takes off with.

http://youtu.be/1bGL5bos43g - Bridge view of car passing underneath. Good fun video of the car passing very close to the camera and under as if on a bridge

http://youtu.be/Syl9bXOpqxY - Excellent video of a complete run from ‘stomp’ to car running to near end of track.

http://youtu.be/51KvN6GOSvQ - Very good view of one of our students stomping and seeing the car released

http://youtu.be/8YKpov1DUO8 - A fun one with our Head – Mr Martlew having a stomp and not quite reaching the end of the track – shows appeal that this project holds for all ages!

http://youtu.be/m79gzhij1MU - Good ‘scale’ view from perspective of rear of car as it is released

http://youtu.be/PifABYg2VXQ - Good view from launcher as car is stomped and reaches far end of 21 metre track! (also below)

Hope you like all the videos and pictures!!

In terms of the project for the primary schools, this is still being developed.

Already set out will be car size and axle widths to suit the track. Kit for each school including a stomp launcher and 6 rockets.

Challenge will to design and construct a vehicle that is both aerodynamic and reflects the Bloodhound ethos.

Criteria for success will be based on car and team identity, quality of car construction – weight and aerodynamic quality – (we are developing a test rig based on a powerful hair dryer mounted so it points directly at the car being measured, and will measure how much the car is pushed backwards by measuring the pull on a very delicate spring balance) and finally how far the car travels and speed – based on speed trap value.

This is not hard work – ‘tis too much fun!!

Phil Worsley

The Joseph Whitaker School