I’ve just seen the latest figures for participation in the BLOODHOUND education programme – over 3,300 schools, over 200 Further Education colleges and 35 Universities. That’s over 10% of all the schools in the UK, which is just incredible. Perhaps the rest of the Project team ought to feel under pressure from the education team – they seem to be outstripping our fund-raising and engineering efforts by a huge margin. Still, our main aim is to create interest in science and engineering, so this is the way that it should be – the education team is out in front and the rest of us are under pressure to keep up!

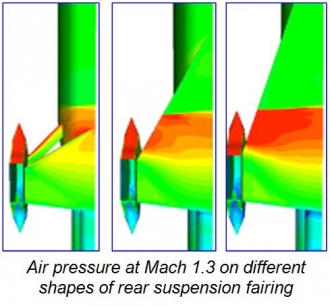

The design office is certainly doing its best to keep up, with the ‘aerodynamic optimisation’ (or ‘getting the back end exactly right’) programme is tearing along. The team has run 56 parametric models in 4 weeks, using the huge computing power available through our IT partner Intel. Rumour has it that the Met Office is now feeling under pressure, as we’re using more computing power than they are.... and, in terms of aerodynamics, we’re forecasting sunshine! A great effort over the last month from Mark Chapman, Bjorn Rodde and Ben Evans, who are giving the rest of us the perfect Christmas present with these results.

The design office is certainly doing its best to keep up, with the ‘aerodynamic optimisation’ (or ‘getting the back end exactly right’) programme is tearing along. The team has run 56 parametric models in 4 weeks, using the huge computing power available through our IT partner Intel. Rumour has it that the Met Office is now feeling under pressure, as we’re using more computing power than they are.... and, in terms of aerodynamics, we’re forecasting sunshine! A great effort over the last month from Mark Chapman, Bjorn Rodde and Ben Evans, who are giving the rest of us the perfect Christmas present with these results.

While the aerodynamics will keep the Car on the ground, it also needs to be dynamically safe as a Car. This includes putting the rear wheels wide enough apart to make sure that the Car cannot roll over. But how wide is that? Looking back at the Thrust SSC data, we saw a peak sideways ‘G’ force of almost 1G – yikes! That is huge (about the same as the maximum cornering force that the average road car will produce). If we put BLOODHOUND SSC’s rear wheels far enough apart to resist that, then the drag will prevent Car from reaching 1,000 mph.

Fortunately, Ron Ayers, our performance expert (and one of the cleverest people I know) has pointed out that Thrust SSC’s wheels would not have generated 1G side loads by themselves – there just isn’t that much grip on the desert. Instead, it appears that the Car developed a couple of degrees of yaw and this created a large aerodynamic side force, which pushed the Car sideways but did not risk rolling it over. We can leave the rear wheels where they are, without any danger of BLOODHOUND SSC rolling over. Suddenly I feel much happier – thanks, Ron.

Fortunately, Ron Ayers, our performance expert (and one of the cleverest people I know) has pointed out that Thrust SSC’s wheels would not have generated 1G side loads by themselves – there just isn’t that much grip on the desert. Instead, it appears that the Car developed a couple of degrees of yaw and this created a large aerodynamic side force, which pushed the Car sideways but did not risk rolling it over. We can leave the rear wheels where they are, without any danger of BLOODHOUND SSC rolling over. Suddenly I feel much happier – thanks, Ron.

We’ve just had some really exciting news of a plan to include recycled materials in the Car, which will reduce the carbon footprint for the Car’s build. This will also give us a great way to include recycling technology in our education programme. We’re just working out the details now – more to follow shortly.

Finally, the chance to put your name on the Fin of BLOODHOUND SSC is proving hugely popular. The Union Flag on the Fin will be made up of thousands of tiny coloured names, which is a great way for us to get children (of all ages!) more involved in this astonishing piece of engineering. Let’s hope that the ‘aerodynamic optimisation’ doesn’t make the Fin too much smaller……

2009 has been an amazing year and I can’t wait to see what’s going to happen during 2010.