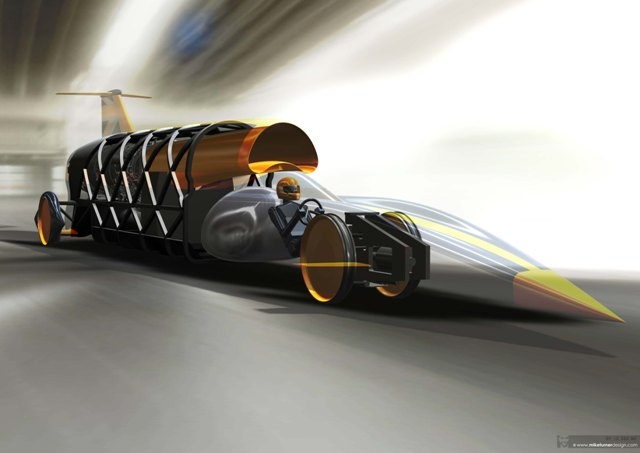

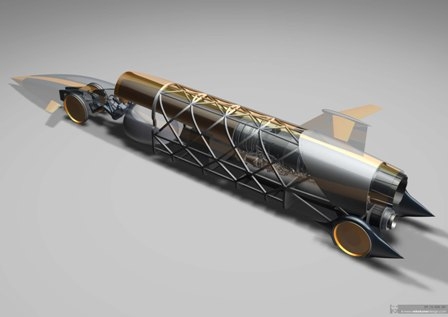

Today, the BLOODHOUND Project publishes the Vehicle Technical Specification (VTS) for its Jet and Rocket powered World Land Speed Record contender. This detailed document makes up Part one of the car’s ‘genome’, Part two, the CAD design files will be published by the Autumn.

The BLOODHOUND Project is a science and education-led initiative aiming to inspire young people to pursue careers in Science, Technology, Engineering and Mathematics (STEM subjects) by showcasing them in the most exciting way possible – by building a car capable of reaching 1,000 mph.

The BLOODHOUND Project is a science and education-led initiative aiming to inspire young people to pursue careers in Science, Technology, Engineering and Mathematics (STEM subjects) by showcasing them in the most exciting way possible – by building a car capable of reaching 1,000 mph.

It is also a world class research and development (R&D) programme. Cutting edge technology projects of this calibre are usually shrouded in secrecy, but a key aspect of the BLOODHOUND mission is to share the adventure – and all the data – with the biggest audience possible.

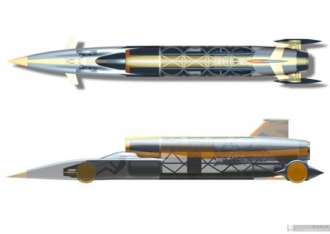

Unlike more traditional motor sport e.g. Formula 1, there is no competitive risk from sharing secrets. World Land Speed Record breaking has few rules, namely: the car must be continuously controlled by a driver and run on four wheels. This means that land speed record challengers have almost total freedom when designing their car and it explains why, in 1997, Thrust SSC, a four-wheel twin jet-engined car, was able to race Craig Breedlove’s single-engined, five-wheeled Spirit of America. Physics levels the playing field, not a book of regulations.

The Genome will be used in the BLOODHOUND Education Programme, which produces curriculum resource materials for all levels of education. Currently 3541 primary and secondary schools, 230 further education colleges and 40 universities, totalling 1.5 million students, are now exposed to real-world case studies based on the jet- and rocket-powered Car, helping to bring their Science, Technology, Engineering and Maths (STEM) lessons to life.

The Genome will be used in the BLOODHOUND Education Programme, which produces curriculum resource materials for all levels of education. Currently 3541 primary and secondary schools, 230 further education colleges and 40 universities, totalling 1.5 million students, are now exposed to real-world case studies based on the jet- and rocket-powered Car, helping to bring their Science, Technology, Engineering and Maths (STEM) lessons to life.

Mark Chapman, Chief Engineer said. “It’s unheard of to share plans in this way in the motorsports or aerospace industry. That’s just one more reason why BLOODHOUND is exceptional and uniquely able to demonstrate the creativity and problem solving involved in engineering, especially at this level. We meet our extended team at events and shows across the country and people love to know the detail. Soon they’ll have enough information to build their own car!”

Components for BLOODHOUND SSC are being manufactured now.