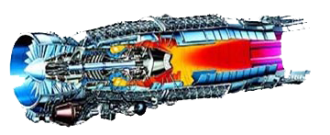

At its simplest level the jet engine can be split into four basic sections

- an intake which channels the air

- a compression stage to raise its pressure

- a combustion stage where the fuel is added

- an exhaust stage where energy is extracted to drive the compressor and the remainder comes out as thrust.

Compressor

The compressor is at the front of the engine, and does the job of sucking and squeezing the air into the engine. It has two sections: a low pressure compressor and a high pressure compressor.

The low pressure compressor does the initial work of taking the air from the intake and increasing its pressure by a factor of about 4:1. It then feeds this air either to the engine core or around the bypass duct.

The air that travels through the engine core then goes through the high pressure compressor, which will raise its pressure a further six times. Some of this air is bled off for cooling various hot-end components (though the term 'cooling' is relative as by now the air temperature is over 500°C.

The bypass air misses out the high pressure compressor and combustor, and most of it rejoins the core flow at the jet pipe. However, some of it is diverted and used to pressurise the bearing chambers and cool various engine components.

Combustor

The combustor is where fuel is added through a ring of sprayers, ignited initially with an igniter plug, and burned. The burning process is self-sustaining until the fuel supply is cut off.

The temperature of the flame is over 2,000°C, which is well above the melting point of the alloys that the casing is made from, so bleed air (see above) is used to provide a cooling flow, and to prevent the flame from touching the casing.

Turbines

The flow from the combustor is fed through two turbines, whose purpose is to extract energy from the exhaust gasses and drive the LP and HP compressors.

The turbines consist of alternate stationary and rotating aerofoil section blades. The stationary blades, known as guide vanes, are attached to the engine casing, while the rotating blades are mounted on the turbine disc which is attached to a shaft driving the compressor.

Again these are operating in conditions far exceeding the melting point of their alloys, and need active cooling from bleed air.

To give an idea of just how much energy is needed to drive the compressor, for a jet engine producing around 60kN of thrust, around 35,000 horsepower (hp) is needed to drive the high pressure compressor. Putting this into perspective, the total thrust of the engine is equivalent to 40,000hp, so almost half the power of the jet is being used to drive its own compressor, with the remainder coming out of the nozzle as thrust.

Nozzle

In the final stage, the exhaust gasses exit the turbine and pass through the jet pipe to the nozzle, which controls the flow out of the back of the engine. In the EJ200 (the jet engine being used in BLOODHOUND), this nozzle can adjust its area to match the engine requirements, both to increase the thrust of the engine and to help control engine 'surge'.

In this engine, additional fuel can be injected into the jet pipe and burned with the aid of the oxygen rich bypass air. This is known as 'reheat', and it provides a significant extra push. The maximum 'dry' (non-reheated) thrust of the EJ200 is 60kN, but when you add a few gallons of fuel into the exhaust, this increases to a maximum 'wet' (reheated) thrust of 90kN. (A reheat is what Americans refer to as an 'afterburner'.)